Imagine a world without your favorite plastic products, from your phone case to essential medical devices. It is almost impossible, isn't it? That is where a top-tier plastic tooling co steps in, making the impossible possible by crafting the intricate molds that bring these items to life. This field is currently experiencing a massive surge in demand and innovation, particularly within the United States, as companies strive for both efficiency and sustainability. Understanding the nuances of plastic tooling co operations is crucial for anyone involved in product development, manufacturing, or even just curious about how things are made. This comprehensive guide will explore the pivotal role these companies play, the cutting-edge technologies they employ, and how they are shaping the future of industrial production, ensuring that tomorrow's products are not only functional but also environmentally conscious. Dive in to discover why plastic tooling co remains a hot topic, poised for continued growth and significant impact across countless industries.

When we talk about modern manufacturing, particularly the intricate world of plastic products that touch every facet of our daily lives, a plastic tooling co is often the unsung hero. These specialized companies design and produce the high-precision molds and dies absolutely necessary for mass-producing plastic components. They are the crucial link in the chain, translating product designs from mere concepts into tangible, functional items, enabling countless industries from automotive and medical to consumer electronics and packaging. This process, which involves expert engineering and meticulous craftsmanship, determines the quality, consistency, and cost-effectiveness of plastic parts. For 2026, the focus for a plastic tooling co is squarely on innovation, efficiency, and sustainability, as market demands push for faster turnaround times, advanced materials, and environmentally responsible production methods. Choosing the right plastic tooling co means ensuring your product's success, as their expertise directly impacts everything from initial design validation to final product performance and market reception. It is a sector driven by continuous technological advancement and an unwavering commitment to precision.

What Does a Plastic Tooling Co Actually Do for Manufacturing?

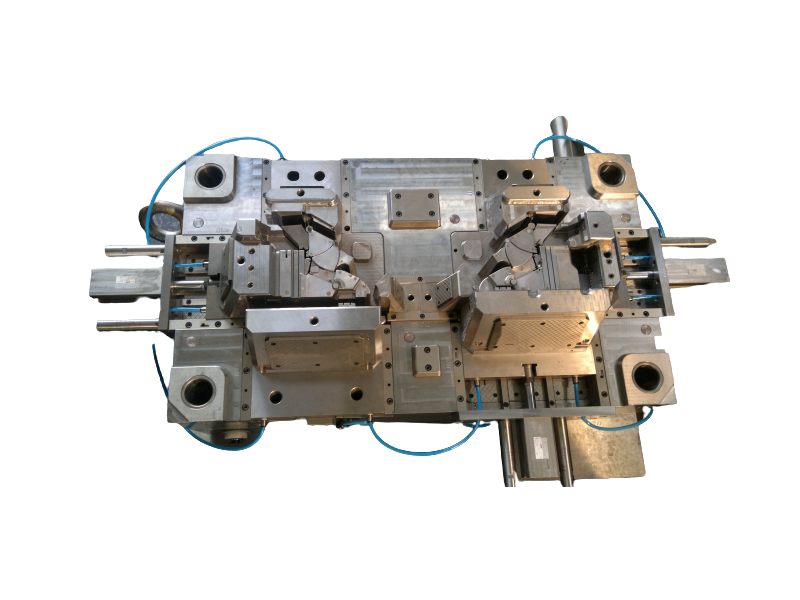

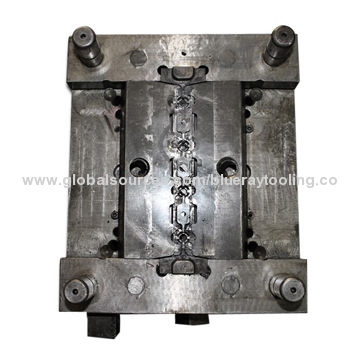

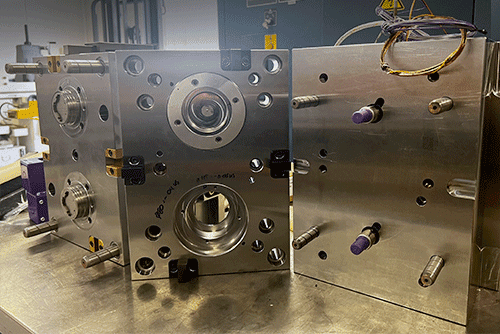

A plastic tooling co serves as the backbone of plastic product manufacturing. They design and create molds, often using Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software, then machine these molds with incredible precision from materials like steel or aluminum. These molds are then used in processes like injection molding, blow molding, or compression molding to produce thousands, or even millions, of identical plastic parts. Their work ensures that every plastic component, from a simple bottle cap to a complex automotive dashboard, meets exact specifications, performs reliably, and contributes to the overall quality of the final product. Without the expertise of a plastic tooling co, the mass production of affordable, high-quality plastic goods would simply not be possible in our modern industrial landscape.

How Has Technology Transformed the Plastic Tooling Co Landscape?

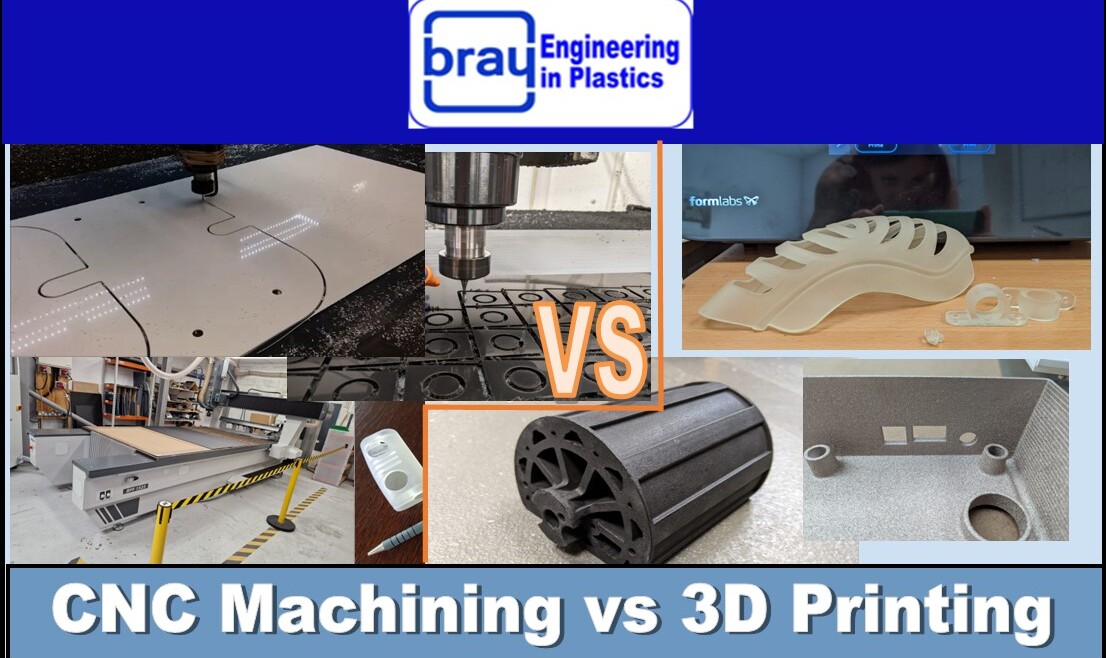

Technology has revolutionized the plastic tooling co industry. Advanced CAD/CAM software allows for intricate mold designs and simulations, predicting material flow and potential defects before physical production. CNC machining ensures unparalleled precision, while additive manufacturing (3D printing) facilitates rapid prototyping and the creation of complex mold inserts. Automation and robotics are increasingly integrated into manufacturing processes, enhancing efficiency and reducing human error. These innovations empower a plastic tooling co to deliver faster, more complex, and higher-quality tooling solutions, meeting the evolving demands of a dynamic market.

Why Is Precision Paramount for a Plastic Tooling Co?

Precision is not just a buzzword for a plastic tooling co; it is fundamental to their entire operation. Slight inaccuracies in a mold can lead to critical defects in the final plastic parts, such as improper fit, structural weaknesses, or cosmetic flaws. Such imperfections can result in costly recalls, production delays, and significant material waste, impacting profitability and brand reputation. Therefore, a plastic tooling co invests heavily in advanced measurement equipment and skilled engineers to maintain microscopic tolerances, ensuring every molded part consistently meets stringent quality standards. This unwavering commitment to precision guarantees component integrity and optimal product performance.

What Are the Key Innovations Driving the Plastic Tooling Co Industry Forward?

The plastic tooling co industry is in a constant state of evolution, driven by the need for greater efficiency, complex geometries, and sustainable practices. One significant area of innovation is in the use of advanced materials for molds themselves, such as specialized tool steels and coatings that offer extended lifespan and improved heat transfer, which directly translates to faster cycle times and reduced production costs for clients. Furthermore, the integration of smart manufacturing principles, often referred to as Industry 4.0, is transforming how a plastic tooling co operates. This includes incorporating sensors within molds for real-time data collection on temperature, pressure, and material flow, allowing for immediate adjustments and predictive maintenance, thereby minimizing downtime and maximizing output. These innovations aren't just about making things faster; they're about making them smarter, more reliable, and ultimately more cost-effective for the companies relying on plastic tooling to bring their products to market. Embracing these technological leaps is what sets leading plastic tooling co companies apart in a competitive global environment, as they continue to push the boundaries of what is possible in plastic part manufacturing.

How Does a Plastic Tooling Co Address Sustainability Challenges?

Sustainability is a growing concern for every industry, and the plastic tooling co sector is actively responding. This involves implementing more energy-efficient manufacturing processes, optimizing material usage to minimize waste during mold creation, and exploring the use of recycled or bio-based plastic materials for the final products themselves. Many plastic tooling co operations are also focusing on designing molds that can produce parts from recycled plastics more effectively, addressing challenges like varying material properties and shrinkage. Furthermore, the longevity of the molds produced is a sustainability factor; a well-designed and precisely manufactured mold from a reputable plastic tooling co can last for millions of cycles, reducing the need for frequent replacements and conserving resources. These proactive steps demonstrate a commitment to environmental responsibility while continuing to deliver innovative and high-quality tooling solutions for the diverse needs of their clients, pushing the boundaries of what a plastic tooling co can achieve in a greener future.

| Aspect | Description |

|---|---|

| Primary Function | Design & Manufacture of Molds/Dies for Plastic Products |

| Key Technologies | CAD/CAM, CNC Machining, Additive Manufacturing, Automation |

| Core Competencies | Precision, Material Science, Engineering, Quality Control |

| Industry Impact | Enables Mass Production Across Diverse Sectors (Auto, Medical, Consumer) |

| Current Trends | Sustainability, Industry 4.0, Rapid Prototyping, Advanced Materials |

| Benefits to Clients | Cost-Efficiency, Quality Consistency, Faster Time-to-Market |

What Others Are Asking?

What exactly does a plastic tooling co do?

A plastic tooling co specializes in creating the precise molds and dies required for manufacturing plastic parts. They translate product designs into physical tooling, which is then used in processes like injection molding to mass-produce consistent and high-quality plastic components for various industries.

Why is precision so critical in plastic tooling co operations?

Precision is critical because even minor inaccuracies in a mold can lead to defects in the final plastic parts, affecting their functionality, fit, and aesthetic. A plastic tooling co ensures exacting tolerances to guarantee consistent, high-quality, and reliable products, preventing costly reworks and material waste.

How has technology transformed plastic tooling co processes?

Technology has revolutionized plastic tooling co by introducing advanced CAD/CAM software for design, CNC machining for ultra-precision manufacturing, and 3D printing for rapid prototyping. These innovations lead to faster development, increased complexity in designs, and improved overall mold quality and efficiency.

What materials are commonly used by a plastic tooling co?

A plastic tooling co primarily uses high-grade steels, such as P20, H13, and S7, for durable molds, and sometimes aluminum for prototypes or lower-volume production due to its easier machinability. The choice depends on the part's complexity, production volume, and the plastic material to be molded.

Can a plastic tooling co assist with product design?

Absolutely, many plastic tooling co companies offer design for manufacturability (DFM) services. They work closely with clients to optimize product designs, ensuring they are suitable for efficient and cost-effective plastic molding, often identifying potential issues before mold production begins.

FAQ

Who benefits from a plastic tooling co?

Manufacturers, product developers, and any company needing custom plastic parts benefit from a plastic tooling co. They serve diverse sectors from medical devices to automotive components, providing essential production tools.

What services does a plastic tooling co offer?

A plastic tooling co offers services including mold design, mold manufacturing, prototyping, mold repair, and often design for manufacturability (DFM) consultation to optimize part production.

Why is choosing the right plastic tooling co important?

Selecting the right plastic tooling co is vital for product quality, production efficiency, and cost control. An experienced company ensures precise, durable molds that lead to consistent, high-quality final plastic parts.

How does a plastic tooling co ensure quality?

A plastic tooling co ensures quality through rigorous design reviews, precision CNC machining, advanced metrology, and thorough testing of molds. They adhere to strict quality control standards throughout the entire tooling process.

Key Takeaways about Plastic Tooling Co:

- Plastic tooling companies are indispensable for mass production of plastic components across all industries.

- Advanced technologies like CAD/CAM, CNC, and 3D printing are vital for modern plastic tooling co operations.

- Precision is the cornerstone of effective plastic tooling, directly influencing product quality and cost-efficiency.

- Sustainability initiatives, including energy efficiency and material optimization, are increasingly important for a plastic tooling co.

- Partnering with the right plastic tooling co can significantly impact product development cycles and market success.

- The industry is continuously innovating to meet demands for faster, more complex, and greener manufacturing solutions.

Precision engineering, advanced material processing, rapid prototyping, sustainable manufacturing practices, critical role in product development, industry innovation, custom mold fabrication, quality assurance, global supply chain integration, automation and robotics in plastic tooling co.

Fine Shop TG2026 FC Noupc Plastics Rubber 2026 1024x1024 An Overview Of Self Tapping Screws Designed For Automotive Fasteners For Automotive1

Best 6 Plastic Spring Clamp In Paris France Shanghai Pentagon Plastics Group Latest News Meet The Toolmaker Another Show Plastics Recycling Conference 2026 Coperion Prc 2026 706x706 Supply Plastic Injection Tooling Wholesale Factory PROSPERITY 3600

DTG Factory Plastic Tooling With Custom DTG Factory Plastic Tooling With Custom Service According To Client S Design The Top 53 Plastic Tooling Dynamic Tool2026 Plastic Surgery The Meeting USA Australian Society Of Plastic 640x300 Mastering The Art Of Cutting Plastic Corrugated Roofing Tips Tools How To Cut Plastic Corugated Roofing

Cost Effective Injection Moulding Find Out More On Our Stand K220 At Iso TRAVELER S COMPANY 2026 Diary Plastic Sheet Passport Traveler S Company 2026 Diary Plastic Sheet Passport (3) 67515 P Tooling COBA Plastics Group Tooling 686x486 Neither Fold Nor Flip Why 2026 S Tri Fold Is The Last Office Tool Image 1768483554 Tri Fold Scaled

Oversize High Precision Plastic Part Tooling For ODM Or OEM Auto Oversize High Precision Plastic Part Tooling For ODM Or OEM Plastic Manufacture With Precision Tooling AVID Tool 6 APR Recyda To Launch Plastic Packaging Assessment Tool Cozart I Oversea Precision Plastic Tooling With Drawing China Oversea Precision Plastic Tooling With

CNC Machining Vs 3D Printing Which Process Is Right For Your Project CNC Machining Vs 3D Printing 1 1107x658 Cost Effective Injection Moulding Find Out More On Our Stand K220 At Image AC Plastics Takes Delivery Of 18 Mould Tools Automotive Tools 2026 850x560 Superior Tooling 2026 Company Profile Valuation Investors 200x200

CHINAPLAS 2026 Plastics Rubber Expo In Shanghai ScrapC Buy Sell Plastech India Expo 2025 Coimbatore Plastics Industry Event.webpSupply Plastic Injection Tooling Wholesale Factory PROSPERITY 3600 Plastic Tooling Plastic Injection Aztech Plastic Tooling Main Photo Henchman Tripod Ladder Plastic End Caps Suffolk Mowers Henchman Tripod Ladder Plastic End Caps 1024x1024

Buy Wholesale China Plastic Tooling Plastic Tooling Global Sources Plastic Tooling A Global Symposium On Plastics And Human Health 1 4 Sponsorship Prospectus Cover Traveler S Company 2026 Plastic Sheet Regular Urban Kit Supply Travelers Company 2026 Plastic Sheet Passport 4 40240006 1022x1022 Plastic Tooling Manufacture Plastic Moulding Company Hull Tooling Hero

PLANEA TU VISITA Expo Pl Sticos 2026 EP26 BRANDBOOK 2026 .webpThe Top 53 Plastic Tooling Vision Plastics Plastic Extrusion Tooling Plastic DW Plastics Tool Manufacture 00067 1500x1000

-67515-p.jpg)